Most Trending Concrete Floor Finishes in 2021 | Xtreme Polishing Systems

There has been a strong trend in modern design for house interiors to employ more sophisticated, contemporary, and low-maintenance materials.

Undoubtedly, concrete has always been a material of choice in flooring projects due to its durability and style versatility. Today, this attractive material gets taken up a notch. As a long-term design option, people have begun incorporating various concrete floor surface finishes into their spaces.

If you are looking to reinvent your home flooring, you have come to the right place!

Here is a rundown of options for sprucing up your concrete floors.

The Advantages of Concrete Flooring

It is important to know what it means to install concrete flooring. Here are some of the main benefits of concrete flooring.

There are three primary reasons why so many homeowners are choosing to use concrete in their homes:

- Versatility: Concrete floors allow a wide array of finishing options.

- Durability: Concrete is a durable and reliable material. It can bear pressure from various sources, including furniture legs, high heels, pets, and others.

- Low-Maintenance: Concrete flooring is extremely low-maintenance. These flooring options are not only easy to clean, but they are also water and chemical-resistant.

Concrete floors are very popular in basements, kitchens, living rooms, and garages; however, you can use them anywhere throughout the house.

Trending Concrete Finishing Options

Here are the most popular concrete floor finishing options in 2021.

Polished Concrete

Simple, natural, and crystal gleaming surfaces are among the most desirable when choosing a new flooring option for your home or business. Polished concrete has skyrocketed in popularity over the years because polished concrete surfaces are extremely long-lasting and absolutely reliable, very cost-effective, and easy to maintain, and it can be incorporated in practically any type of environment, whether it be residential, commercial, or industrial settings.

Concrete Sealers

For concrete floors that are constantly exposed to water or get connected down the road, concrete floor sealers may be the best choice.

Concrete sealers are excellent finishing options to achieve a gorgeous sheen that provides a thin, protective layer over your floor. Apply concrete floor sealers evenly to achieve a consistent, uniform matte finish that hardens once dry.

A word of caution, though: if you choose this alternative, when compared to other finishes, this one will show wear more quickly than the others on this list. However, you will not have to spend a fortune to finish the work. Contractors advise that, despite the strong finish, concrete sealers are more flexible than other flooring materials.

Concrete Dyes and Stains

Our supply of concrete stains and dyes enhance the overall look of concrete while complementing the architectural features of the surface.

Concrete dyes and stains produce earth tones and vibrant colors on concrete surfaces. There are a few important factors to consider when you choose decorative concrete methods like staining or dying your concrete floors; determine the type of concrete you’re coloring, pigment selection, water content, mixing ratio, and unique finishing techniques to help you achieve a beautifully decorated surface.

Color Hardeners

Color hardeners are frequently used in conjunction with chemical staining to get darker colors on concrete floors. This finish comes in the shape of a powder that you sprinkle on top of freshly built concrete. The moisture will provide an appealing color on the surface when the powder gets blended with water in wet concrete.

Acid Stain

If you want to add color to your concrete floor, you can use chemical staining, particularly acid staining. Acid staining is one of the most popular ways of staining concrete floors in homes.

Because it leaves behind random details, acid staining transforms plain cool gray concrete into something more appealing. When choosing a color for your concrete floor, you have two options: a neutral that blends in with the rest of the room’s design or a bold color that stands out. You can use a protective epoxy coating or a mechanical polish for the finishing touches.

Water-Based Stain

A water-based stain is a fantastic choice if you want to move beyond the delicate color palette of an acid stain and explore the complete spectrum of hues. Water-based stains are less vibrant than oil-based stains, but there are dozens of shades to pick from, including metallic tints.

Moreover, water-based stains contain fewer Volatile Organic Compounds (VOCs), making them safer to use. Furthermore, because each chemical reaction occurs upon application, the final color will be pretty constant throughout.

Epoxy Resin

Epoxy resin is the most common approach and surely one of the most popular finishes to seal and protect concrete floors. Also referred to as epoxy coatings, these materials are long-lasting, come in a wide range of colors, and produce a beautiful gleaming finish.

Epoxy coatings provide a pleasant, glossy finish to concrete floors which are subject to heavy foot activity, however, this material should not be used on outdoor concrete projects.

Epoxy coatings are the way to go if you want a consistent color with a foundation that can withstand abrasion and chemicals. Epoxy finishes getting introduced by manufacturers today are self-leveling, self-dispersing, and anti-static.

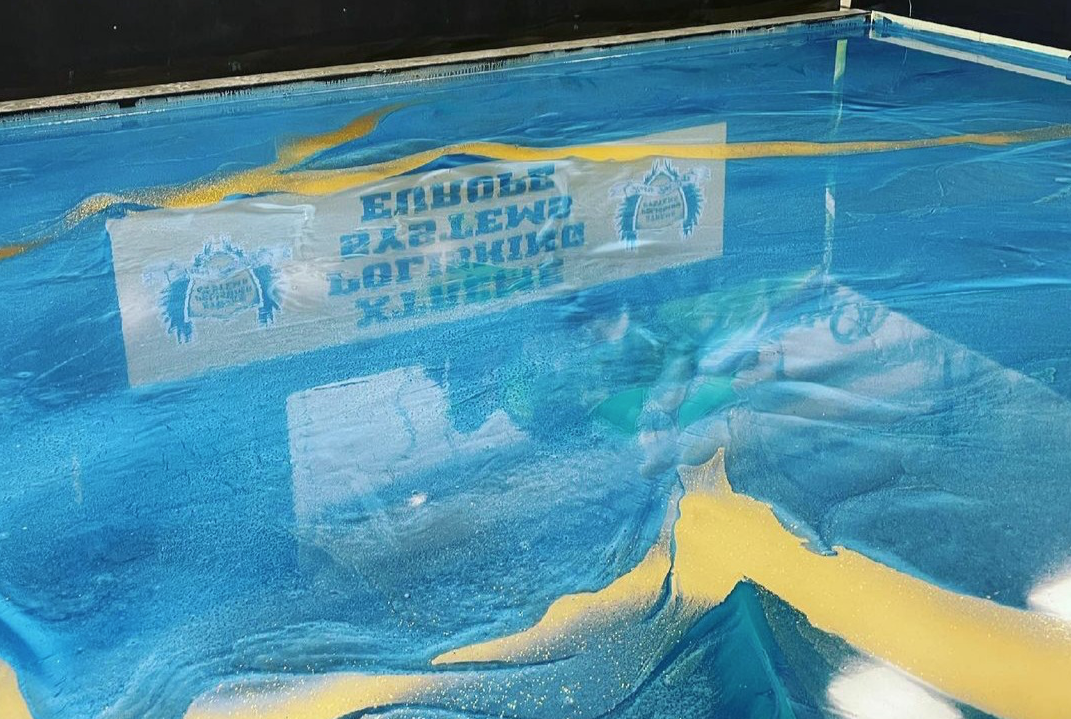

Metallic Epoxy

Metallic epoxy is simply a design option out of the multitude of epoxy resin finishes available in the market and produces such rigid durability, just like a standard epoxy resin finishes. However, this finishing option gives your floor a STUNNING metallic sheen as well as a unique movement and decorative flow of color.

Contractors and DIY’ers around the world are exercising their abilities by installing these decorative floor coatings to create a true one-of-a-kind surface that is unique to you and your style preferences. Metallic epoxy is a fun, inventive, and artistic way to develop the most extraordinary surface finishes that are aesthetically appealing, cost-effective, and maintainable surface finishes that are safe enough for your family, friends, guests, and clients.

Epoxy Flake/Chip

Epoxy flake/chip finishes are excellent methods to give your concrete floors and the surrounding environment some texture and a distinct aesthetic appearance. This durable finishing option is incredibly resilient, UV-resistant, sustainable, and very easy to clean.

Furthermore, decorative epoxy color chips/flakes get dispersed into a liquid epoxy of your choice in these procedures. Epoxy flakes/chips are available in a wide range of color combinations, designs, and blends that will appear uniformly textured and then sealed with a resilient clear topcoat for extra protection.

Epoxy flake/chip finishes are designed to accent, balance, complement, and influence any décor. Our unique approach to customization efficiently personalizes any space.

Conclusion

Nowadays, there are various treatments from which to pick to make your concrete floor look appealing. Remember, however, that regardless of the finishing style you choose, your concrete floor’s long-term and high-quality appearance is contingent on good surface preparation and continuous floor maintenance.

Resources, Guidance, and Support

Our complete Concrete Floor Guide and Epoxy Blog each exhibit helpful industry knowledge and resourceful product expertise for contractors, do-it-yourself individuals, businesses, and property owners seeking instant direction support.

The professionals at Xtreme Polishing Systems understand that each individual concrete surface must be treated differently based on the slab’s current condition, and it’s very common for unforeseen complications to occur after hours while still on the job site. Our clients deserve immediate access to expert tips and customer support that may be useful for various reasons which may occur in this ever-changing industry.

Questions? Our professionals are readily available to answer any questions or assist with your inquiries, so feel free to contact us at (877) 958-5732 with your questions and inquiries. Browse our website www.shopxps.com today for online purchasing , or call for our in-store/curbside pickup services.